CONTACT US Today!

+91 9810626301Are you searching for cost-effective PSA medical oxygen generator

Contact us for for PSA medical plant setup at best prices.

-

Adsorption-based Technology

-

Long Life

-

95% Purity

-

Responsive Service

Quick Contact

PSA medical generator

PSA medical oxygen plant uses adsorption technology for separating oxygen from other gases. PSA technology is just as popular as cryogenic distillation but it can only generate oxygen with low purity on a small scale. Higher purity oxygen production is not possible with the PSA technologies. Some micro and small scale hospitals and businesses go for it. For professional level medical oxygen retailing it is important that you go for air separation products made with the very efficient cryogenic air separation. Mostly PSA plants come in small sizes ranging between 10m3/hr to 250m3/hr.

PSA oxygen plant

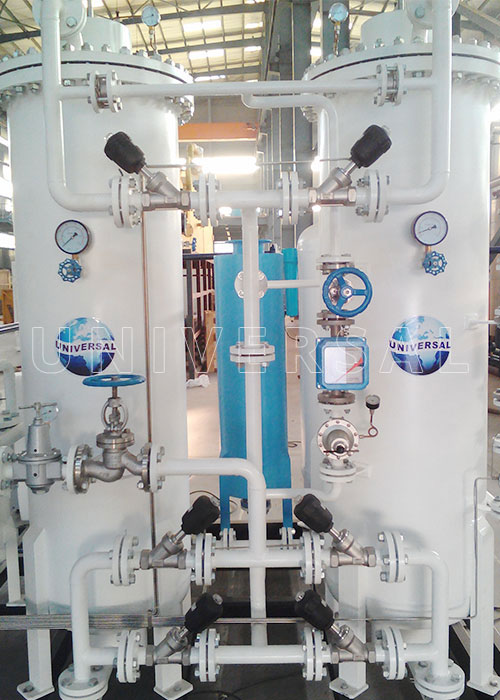

There are two popular techniques for separating atmospheric air into constituent gases such as nitrogen, oxygen and argon. Separation of gases is important for obtaining high purity oxygen or other desired gas as per your requirement. No doubt, we have to use an industrial process for achieving the level of purity. PSA O2 plant comprises of twin towers containing ZEOLITE for preferential adsorbing of nitrogen while allowing oxygen to pass though as a product gas. It is a simple process that can generate oxygen with purity up to 95%. PSA plant cost is comparatively less than that of cryogenic air separation plants but then they deliver far superior performance and higher purity.

PSA medical oxygen generator

Hospitals need round the clock supply of medical grade oxygen for administering to the patients. However, there are strict specifications mandated by national medical bodies and the WHO for generating medical oxygen. PSA medical oxygen generator is used for onsite production of O2 in micro to small hospitals. Firstly, it is imperative that the generator must be fabricated with ASME quality certified materials. All parts and components used in the making of PSA generators must be procured only from internationally reputed OEMs. And, the manufacturing process must comply with globally approved standards of quality. Compliance with medical specifications is uncompromising.

Working principle of PSA medical oxygen generator is based on the adsorption technology. The adsorption technology takes the atmospheric air pushing it through one of the twin towers. Adsorbing material inside the tower is called ZEOLITE. On passing through a bed of ZEOLITE, nitrogen molecules present in the air get adsorbed while oxygen molecules are allowed to pass through. Thus, oxygen becomes the product gas while nitrogen is evaporated back into the atmosphere. The 2nd tower is switched on for processing the compressed air when the 1st tower becomes saturated with nitrogen. The process is widely used in industries for getting high purity oxygen.

Hospital Oxygen Generator

We have specially conceptualized the small scale hospital oxygen generator plant for fulfilling the high oxygen requirements of small hospitals and industrial businesses. Mostly, they need oxygen cylinder filling plants as they meet the requirements of customers through cylinders. Installing mini or micro O2 plant is the best option for small hospitals or businesses. This provides you freedom from having to worry about oxygen supply, which is at times erratic. It needs no emphasizing that onsite installation is the only way for getting uninterrupted and reliable high purity oxygen supply. Moreover, our mini and micro medical oxygen plant price is low compared to the competition.